1. Standard

Standard:Client Agreement2. Chemical Composition

| Elements | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | N | V |

| Min | 0.35 | 0.15 | 12.0 | 0.8 | 3.5 | 0.02 | |||||

| Max | 0.03 | 0.65 | 0.020 | 0.008 | 0.4 | 14.5 | 1.6 | 5.5 | 0.25 | 0.020 | 0.11 |

| Actual value | 0.02 | 0.39 | 0.010 | 0.002 | 0.24 | 12.8 | 1.05 | 4.3 | 0.06 | 0.010 | 0.1 |

3. Mechanical Properties

| Mechanical Properties |

Tensile Strength MPa |

Yield Strength MPa |

Hardness HBW/HRC |

Elongation % |

| Min | 862 | 758 | 26HRC | 12 |

| Max | 965 | 32HRC | ||

| Actual value | 978 | 864 | 30HRC | 20 |

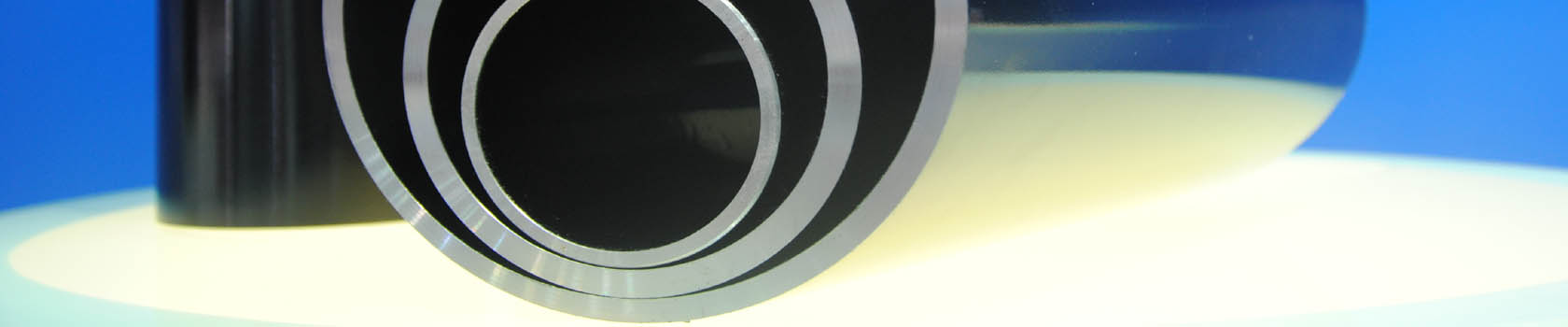

4. Typical Size

| Size |

Outside Diameter Mm |

Permissible Variations in Outside Diameter mm |

Wall Thickness mm |

Average Wall Permissible Variations in Wall Thickness |

| 110×35 | 110 | ±1.5D | 35 | ±10%S |