1. Standard

Standard :ASME SB4442.Chemical Composition

| Elements | C | Mn | P | S | Si | Cr | Mo | Ni | Ti | Nb | Co | Fe | Al |

| Min | 20 | 8 | 58 | 3.15 | |||||||||

| Max | 0.1 | 0.5 | 0.015 | 0.015 | 0.5 | 23 | 10 | 0.4 | 4.15 | 1.0 | 5.0 | 0.4 | |

| Actual value | 0.035 | 0.01 | 0.0069 | 0.002 | 0.046 | 21.81 | 8.7 | 63.9 | 0.2 | 3.54 | 0.026 | 1.02 | 0.16 |

3.Mechanical Properties

| Mechanical Properties |

Tensile Strength MPa |

Yield Strength MPa |

Elongation% | Grain Size | |

| Min | 690 | 276 | 30 | ||

| Max | |||||

| Actual value | 848 | 530 | 44 | 7 |

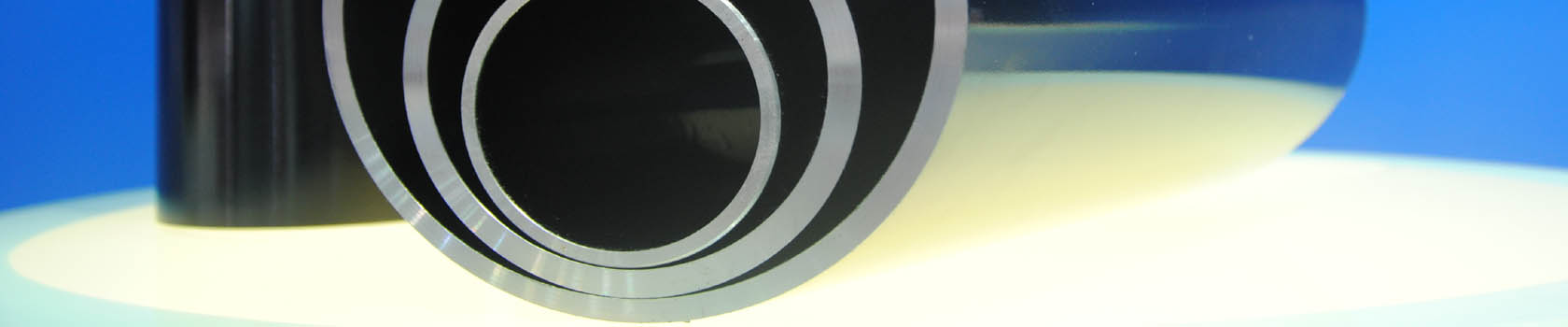

4. Typical Size

| Size |

Outside Diameter Mm |

Permissible Variations in Outside Diameter mm |

Wall Thickness mm |

Average Wall Permissible Variations in Wall Thickness |

| 48.3*3.68 | 48.3 | ±0.25 | 3.68 | ±10%S |

5. Typical Application Environment

The low carbon alloy 625 after softening annealing is widely used in the chemical process industry. It can be used as a thinner structural parts due to its excellent corrosion resistance and high strength performance .The 625 alloy also can be applied to the working conditions of contact with sea water and high mechanical stress.The typical applications:

1) Organic chemical process components containing chlorides, especially where acid chloride catalysts are used.

2) The material is used in digesters and bleaching ponds in the pulp and paper industry.

3) Used for absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, guide plate and flue pipe in flue gas desulfurization system.

4) Equipment and components used in the manufacture of acid gas environment.

5) cetic anhydride reaction generator.

6) Used for sulphuric acid condenser,components of making acid gases.