1. Standard

GB/T8162 GB/T3077CustomerTechnology Agreement

2. Chemical Composition

Test Method :GB/T222 GB/T4336

| Grade | C | Mn | S | P | Si | Ni | Cr | Cu | Mo | |

| 42CrMo | min | 0.38 | 0.50 | -- | -- | 0.17 | -- | 0.90 | -- | 0.15 |

| max | 0.45 | 0.80 | 0.025 | 0.025 | 0.37 | 0.30 | 1.20 | 0.20 | 0.25 | |

| actual value | 0.43 | 0.70 | 0.006 | 0.011 | 0.23 | 0.02 | 0.99 | 0.03 | 0.19 | |

| 35CrMo | min | 0.32 | 0.40 | -- | -- | 0.17 | -- | 0.70 | -- | 0.15 |

| max | 0.40 | 0.70 | 0.025 | 0.025 | 0.37 | 0.30 | 1.10 | 0.20 | 0.25 | |

| actual value | 0.36 | 0.65 | 0.008 | 0.0151 | 0.25 | 0.02 | 1.02 | 0.03 | 0.18 | |

3. Mechanical Properties

Test Method :GB/T228 GB/T229 GB/T2975 GB/T223.1

| Grade | Rm(MPa) | Rp0.2(MPa) | HBW | Elongation % in 4D | Reduction of Area % |

CVN/20℃ Longitudinal AVG(J) |

| 80KSI-42CrMo | ≥655 | 552-655 | ≤241 | ≥20 | ≥45 | ≥40 |

| actual value | 727 | 598 | 223 | 26 | 55 | 141 |

| actual value | 745 | 625 | 230 | 26 | 54 | 135 |

| 110KSI-42CrMo | ≥862 | 758-965 | 270-320 | ≥15% | ≥40% | ≥34 |

| actual value | 925 | 817 | 275 | 18 | 62 | 105 |

| actual value | 969 | 857 | 285 | 18 | 60 | 92 |

| 125KSI-42CrMo | ≥965 | 862-1034 | 285-341 | ≥14% | ≥40% | ≥54 |

| actual value | 1041 | 936 | 302 | 18 | 55 | 78 |

| actual value | 1055 | 964 | 308 | 17 | 56 | 85 |

| 135KSI-42CrMo | ≥1080 | ≥932 | 300-360 | ≥13% | ≥45% | ≥54 |

| actual value | 1117 | 1027 | 330 | 15 | 52 | 65 |

| actual value | 1124 | 1036 | 338 | 14 | 54 | 73 |

4. Typical Size

| Nominal Size | OD/mm | OD Tolerance | WT/mm | WT Tolerance |

| φ101.6*19.8 | 101.6 | ±1% | 19.8 | ±10% |

| φ114*25.4 | 114 | ±1% | 25.4 | ±10% |

| φ119*31.5 | 119 | ±1% | 31.5 | ±10% |

| φ133*19 | 133 | ±1% | 19 | ±10% |

| φ178*22 | 178 | ±1% | 22 | ±10% |

| φ180*23 | 180 | ±1% | 23 | ±10% |

| φ216*53 | 216 | ±1% | 53 | ±10% |

| φ250*28 | 250 | ±1% | 28 | ±10% |

| φ255*43 | 255 | ±1% | 43 | ±10% |

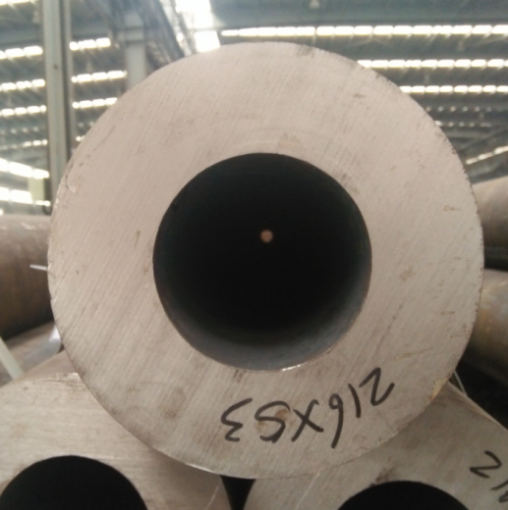

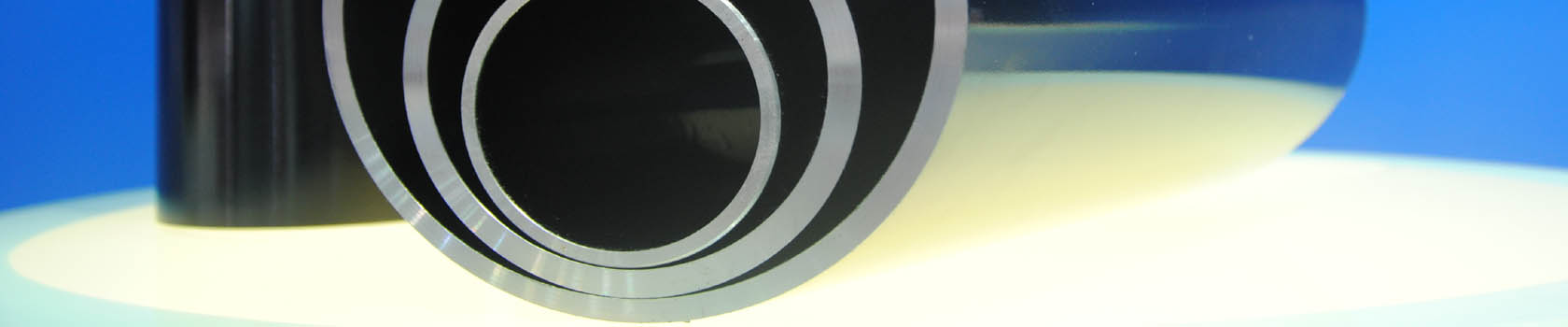

5. Product photos